If you own a car, you must be well aware of the portion of the life income that you have spent on it. You probably wish to have the best. One of the tedious parts of owning a vehicle is its maintenance. Like humans, even the car starts having specific issues with time. No one likes to see their car damaged.

One of the most common issues is to get the door panels fixed. It may be because of several reasons. It can be simply because you think the door panels have been quite old and have severe dents and rust formed on it. One other thing could be they are destroyed due to some mishappening.

How do You Fix It?

Protecting your panels from corrosion and getting it back in a way that doesn’t fall apart again is quite a task. With the advancement in the automotive field, it is now not only possible but a comparatively easy process. Several automotive body panel bonding adhesives are available in the market today. What is an automotive panel adhesive? It is a non-metallic substance that, when applied to one of the two surfaces allows them to bind in a way that cannot be easily separated. It holds the parts together and safeguards them from corrosion until a long period.

How to Use Panel Adhesives?

While adhesives make your work easier, you need to make sure that you follow proper instructions for its usage, or else it might end up spoiling the panel and the surface you want to bond it to. To lessen your burden, we have made a small guideline list for you. Follow the steps given below to make sure everything goes right.

1) There might be paint, rust or contamination on the surfaces, get it removed.

2) Straighten, clamp, and check fitting alignment after cleaning it.

3) Using a cartridge gun, apply enough adhesive in the areas to be bonded.

4) Spread the adhesive appropriately and clamp the panel to the surface. Make sure

5) Remove any extra squeezed out adhesive and let it dry for 4 hours minimum. Wait for a day before getting it back to use.

Numerous auto body panel adhesives are available in the market nowadays. But when it’s a matter of your costly possession, you would, of course, want the best panel bonding adhesive. Don’t worry. We are here to save you from a lot of worry and efforts as we have done our research and brought you some shortlisted panel bonding adhesives.

Best Panel Bonding Adhesive

1. 3M Panel Bonding Adhesive 08116

The best adhesive is not only known for its performance but also its recommendations and customer satisfaction. Well, if you are looking for all of these, 3M Panel Bonding Adhesive 08116 has it all. It meets all your expectations and requirements. It is even recommended by various OEMs and customer reviews that portray the satisfaction level it provides to its users.

Pros

- It adheres to a wide variety of properly prepared steel and aluminum substrates.

- It can even be used on many plastic and composite substrates.

- It can be welded or rivet bonding during working time.

- It cures at room temperature. The addition of heat will accelerate the curing process.

- It provides corrosion protection for a lifetime guarantee.

Cons

- If absorbed by skin, it may cause allergic reactions.

- May irritate eyes, nose, and digestive tract if inhaled.

2. Norton 636425-06420 Speedgrip Metal Panel Acrylic Adhesive

If you are a person who wishes to have amazing results in a short period, then Norton 636425-06420 Speedgrip Metal Panel Acrylic Adhesive proves to be the best choice for you. It is known for its quality of results and the precious time it saves.

Pros

- It is specially designed for metal to metal bonding.

- The approval of the OEM provides quality assurance.

- It comes with lifetime corrosion and a performance warranty.

- It does not require any welding procedures.

- It is easy to apply and is ready to use just in 75 minutes.

Cons

- It is not preferable for any other substrate other than metal.

- It is acrylic in nature, so it might not seem that heavy and may cause harm if contacted directly.

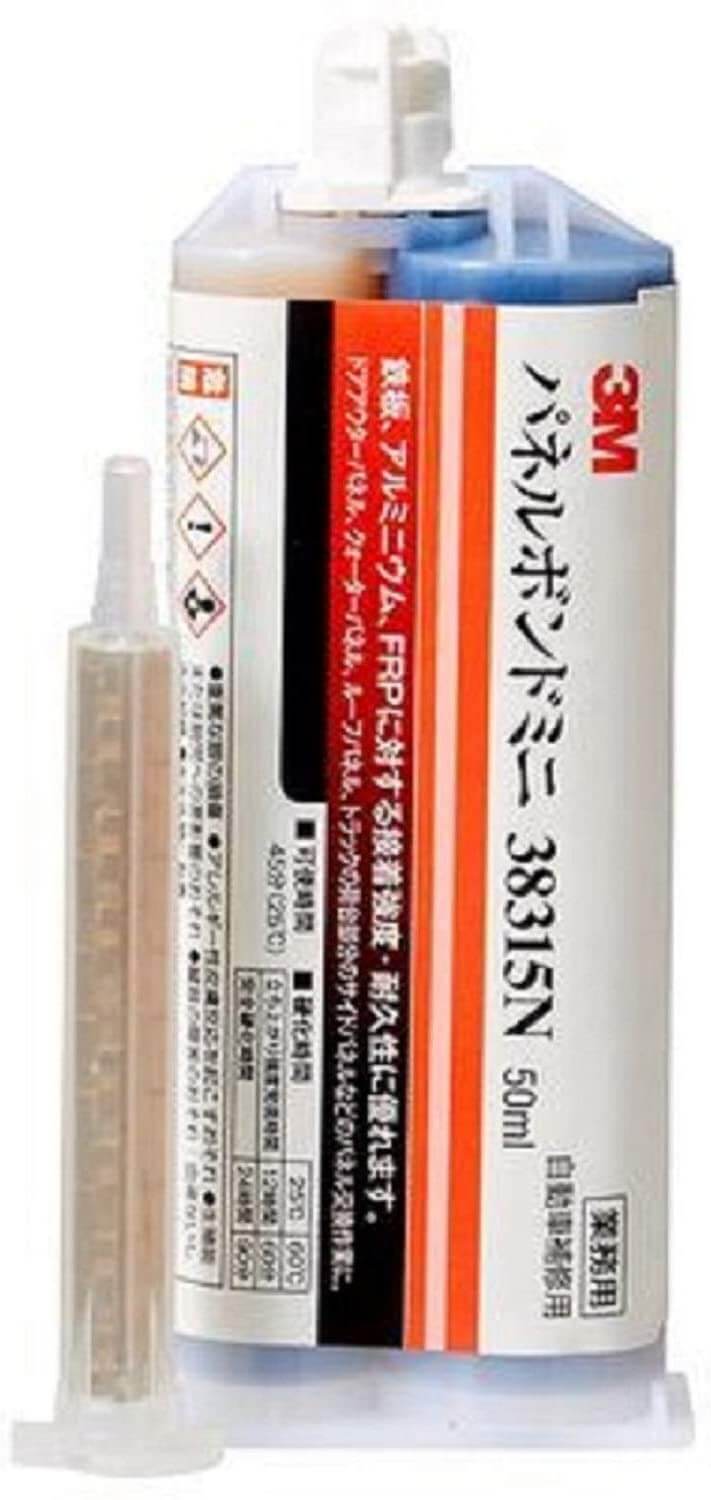

3. 3M Panel Bonding Adhesive 38315

If you are looking for the best panel adhesive for your automobile, 3M Panel Bonding Adhesive it is. You may get disappointed if you turn up to other adhesives, but 3M Panel Bonding Adhesive 38315 will never let you down. This two-component epoxy adhesive is known for its high performance.

Pros

- It is used to form a strong bond on aluminum, steel, SMC, and traditional fiberglass.

- It also bonds a variety of non-structural components.

- It can be used to reinforce welded or riveted structural components.

- The bond created cannot be hampered until a long period.

- It saves the metal from rusting and is durable.

Cons

- It is harmful if it comes in contact with the skin. Using an applicator is recommended.

- It might hurt your nostrils. A good ventilated area is recommended.

4. Speedokote Panel Bonding Adhesive

The Speedokote Panel Bonding Adhesive is a Methyl Methacrylate based adhesive designed for bonding doors or quarter panels. It can be used to form bonds in cold rolled steel, galvanized aluminum, SMC, fiberglass, and other composites. It gives you excellent adhesion within a few hours.

Pros

- It takes around 30 to 60 minutes of work time.

- It does not require a primer.

- The clamp time is limited to 4 hours. It means you the car is ready to use within 5 hours at the max.

- It consists of sag resistance. The adhesive does not bulge up.

- It requires a mixture of 1:1 ratio.

- It can be cleaned easily by a dry cloth.

Cons

- If the components are not mixed properly, it may not lead to desired results.

- Inadequate spraying may also cause errors in bonding.

- It is risky and hurtful if it touches the eyes, nose, or skin.

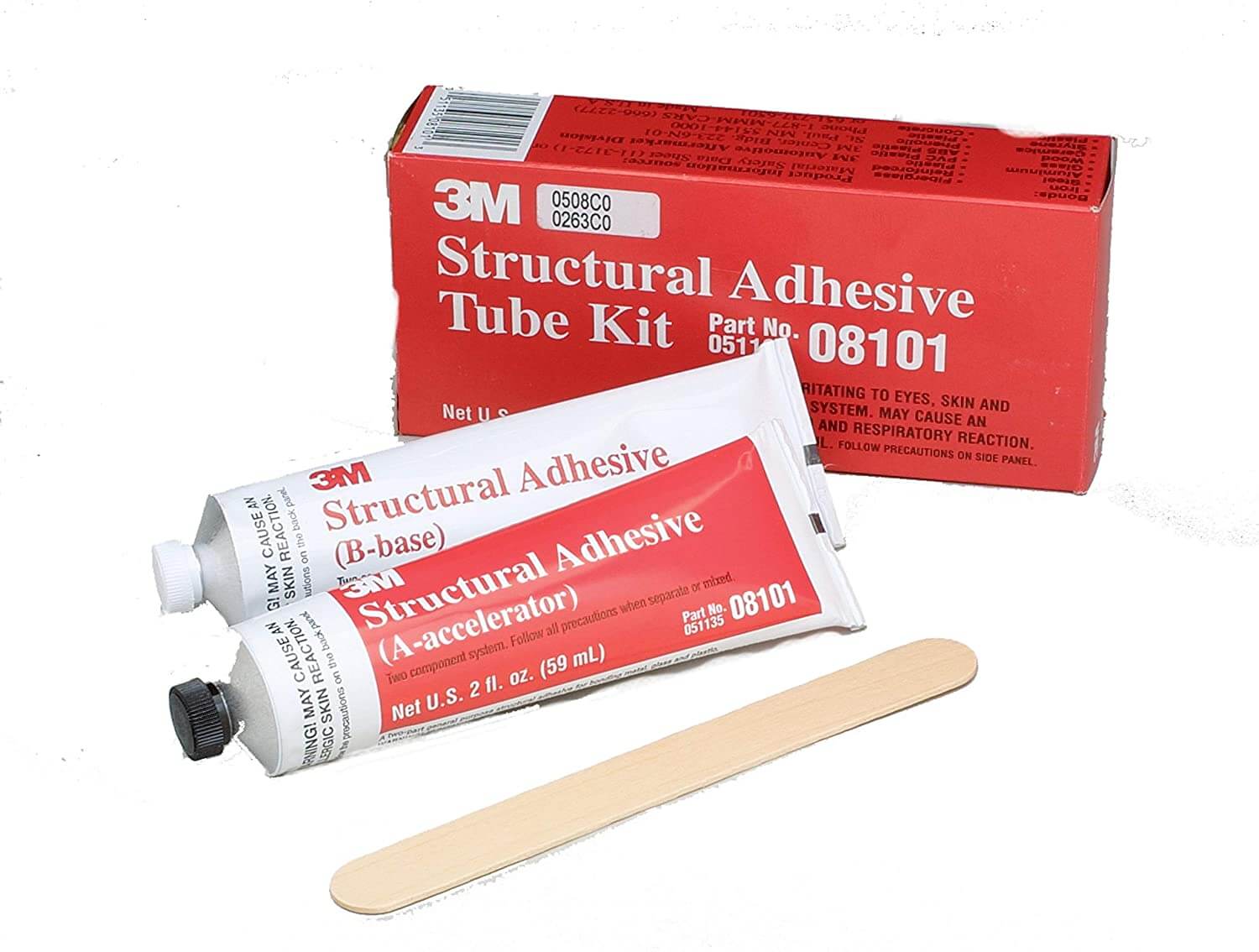

5. 3M Structural Panel Bonding Adhesive 08101

3M Structural Panel Bonding Adhesive 08101 is a specific purpose adhesive that can be used to bond two separate metal parts. It is generally considered as a maximal metal adhesive. If you want your adhesive only to be used for the panel bonding process, then you should opt for this one.

Pros

- It creates a good bond between metal surfaces.

- It takes about 5 to 6 hours to have it back in use.

- It protects from rusting.

- It is in the form of tubes. This makes it easy to use.

- Even a small amount can create a more significant impact.

Cons

- Disproportion in measurements of usage of tube components can hamper the results.

- Under poor ventilation, it may hurt your nostrils.

Conclusion

Now that you have read so far, you are aware of the following:

1) An adhesive is a non-metallic substrate that binds the metal panels with the surface.

2) While buying an adhesive, make sure you choose the one that is used for metal bonding.

3) Certain precautions are necessary while using an adhesive as it contains components that could be harmful to your skin, eyes, and nose. They are,

- Wear a PPE to protect your eyes.

- Wear highly protective gloves while using the adhesive.

- Try not to inhale the adhesive smell as it may damage your nostrils.

- Use the adhesive in a well-ventilated place.

4) Can you use the body panel adhesive without any extra instrument? No. It is necessary to either use the adhesive gun or the adhesive spray for applying the glue correctly.

All the products that are shortlisted are the best as per our knowledge and research. However, many people do question us as to which is the best one. We are unable to choose one, but if we have to recommend only one, we would love to recommend 3M Panel Bonding Adhesive 08116. We hope we have made the selection process a bit easier for you. If you have any doubt, you can always get back to us or check the product features on Amazon. Happy bonding!

Hello, I am Stephen Lombardo. I want to expand my automotive business. I have one large vehicle garage, and I like to do a car wash, repair and joint the cars, and motors parts. If you want to buy any car or vehicle accessories, feel free to reach out with our contact email.