The crankshaft position sensor is the part of the vehicle’s engine that monitors the rotation speed and position of the crankshaft. If this sensor malfunctions, then it can cause issues with your car’s performance or even prevent it from starting. Fortunately, you can manually relearn a faulty crankshaft position sensor in just a few ways.

When trying to temporarily fix a crankshaft position sensor, make sure that all electrical components are turned off before beginning any repairs to avoid injury or damage to your vehicle’s wiring system.

Next, disconnect its connector wire harnesses using an appropriate tool, such as pliers or socket wrenches. Then use an ohmmeter to measure resistance between each terminal of the crank angle signal generator while rotating its shaft by hand until you reach maximum resistance readings for both terminals; this will indicate that you have reached the top dead center (TDC).

Afterward, reconnect all disconnected wires and start up your engine; if everything was done correctly, then the ECU should be able to recognize TDC without any further calibration being required from you!

So in the article, I will discuss the following topics: relearning and temporary fix for crankshaft position sensor problem, what happens if you don t relearn a crankshaft position sensor, how do you program a crankshaft sensor and finally how do you manually relearn a crankshaft position sensor

Related Article:

- At Home Temporary Fix For Bad o2 Sensor

- Causes & Symptoms of a Bad Crankshaft Position Sensor

- Camshaft Position Sensor Bank 1 Location and Meaning

- How To Reset Camshaft Position Sensor, No Start

What happens if you don t relearn a crankshaft position sensor

If a crankshaft position sensor is not relearned, it can lead to a variety of issues with the vehicle.

Here are some reasons that may require you to relearn and reset the crankshaft position sensors are:

- When you replace camshaft position sensor

- When you replace the ECU of you car

- And if the battery of your car was replaced

So what happens if you don’t relearn a crankshaft position sensor? A couple of issues might arise, and the most common one is that your car engine will be unable to start or run properly.

This could be due to an incorrect signal being sent from the sensor, which would prevent fuel and spark delivery from occurring at optimal levels for proper operation.

Moreover, if this problem goes unresolved for too long, then other components, such as catalytic converters, may become damaged or prematurely worn out due to improper combustion cycles and misfires caused by inaccurate readings from the crankshaft position sensor.

Other issues that might arise when you fail to Relearn the Crankshaft Sensor are follows:

- The check-engine light comes up on the dashboard

- The Engine performance will be reduced

- A high fuel consumption or poor Fuel efficiency.

- Starting the car or engine becomes difficult.

- Heightened vibrations and the car will start to rough idle

- A shaking or shuddering, and jerking of the vehicle.

- The car begins to stall

Temporary fix for crankshaft position sensor

If your car experiences issues related to its crankshaft position sensor, there are some temporary fixes you can try before taking it to a mechanic for repair or replacement.

- Identifying what type of problem you are dealing with is important. Suppose the problem is caused by debris blocking the signal from reaching its destination. In that case, cleaning out any dust build-up should be enough to restore normal functioning temporarily until more permanent repairs can be made.

- In addition, checking all wiring connections between components may reveal loose wires that could interfere with the proper operation; simply tightening them up should solve most minor problems like these as well as restore communication between parts so they work together again.

- Finally, replacing old spark plugs and filters may help improve overall performance while potentially resolving issues related to your car’s crankshaft positioning system since worn-out parts will not function as efficiently.

So how do you manually relearn a crankshaft position sensor? Let’s discuss that now.

How do you program a crankshaft sensor?

There are several steps involved in programming a crankshaft sensor, which can vary depending on the make and model of the vehicle being worked on.

The first step is to locate the correct wiring harness connector, where you will find two wires connected to your crankshaft position (CKP) sensors; these should be labeled “A” or “B” according to their respective positions relative to each other inside your engine block.

Once located, use an ohmmeter or digital multimeter set at its highest resolution range setting (usually 20–200 ohms) to measure resistance between both pins while rotating your crankshaft by hand until you reach the maximum resistance value, which indicates that both CKP sensors have been triggered simultaneously.

This indicates that they have been properly aligned with each other during the installation process.

Once alignment has been confirmed, the next step would be to connect the power supply from the battery directly into CKPs connectors; using appropriate gauge wire based on manufacturer specifications.

Test the newly installed system by turning on the car’s ignition switch and observing whether readings from the dashboard correspond accurately with what was expected during the initial setup procedure earlier on. If everything checks out, you’ve successfully programmed your new crankshaft position sensor!

Note that:

In some vehicles, to program a crankshaft, you will need to connect it with an appropriate diagnostic device that allows you to access its parameters from within your vehicle’s computer system.

Once connected, you will need to adjust several settings, such as idle speed, spark plug gap size, air/fuel mixture ratio, etc., before calibrating it with specific values according to manufacturer specifications listed in your owner’s manual.

After all of these steps have been completed and verified through testing procedures such as running engine diagnostic tests under various driving conditions, your computer should now be properly programmed.

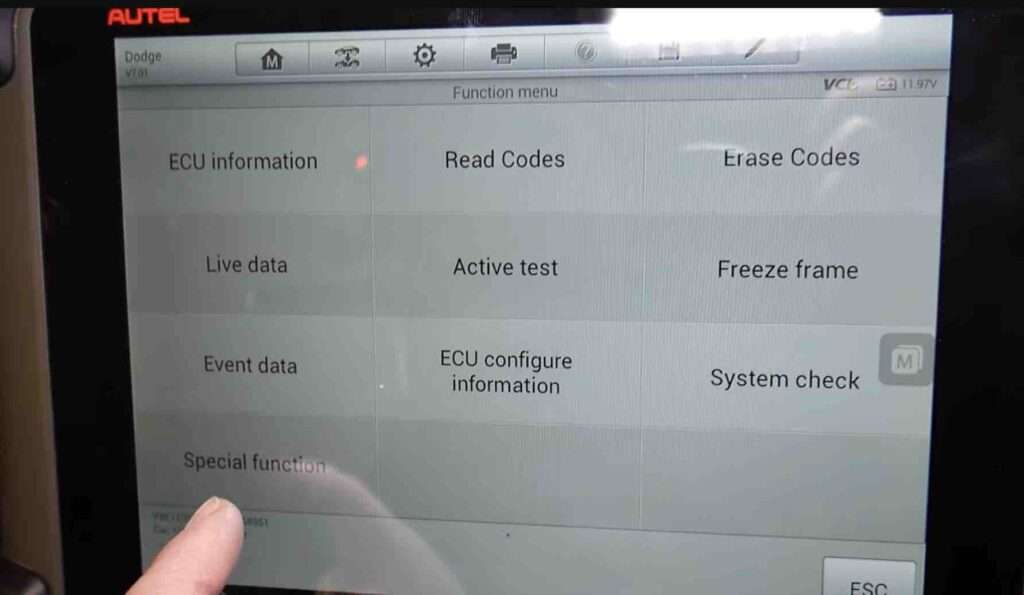

How to Relearn a Crankshaft Position Sensor with scanner

The steps you will need to do in order to relearn or reset a crankshaft position sensor will be slightly different for various vehicles. And it may also vary depending on the OBD scanner you are using and your car type. However, the steps I’ve included below will help you.

Please note though the steps to relearning crankshaft position sensor may be simple, it definitely requires only an advanced OBD scanner and not simpler once here.

So now that you have your scanner ready, follow this steps:

- You can start by connecting the OBD scanner device to your car’s diagnostic port. The diagnostic port is located under the dashboard on the driver’s side, just below the steering wheels. On rear cases for some vehicles, the port can be found under the dashboard or around the center console on the passenger’s side.

- Now you have to turn on the ignition, but don’t start the car engine.

- You have to then select the “Relearn Crankshaft position sensor” function in the OBD tool. This function is not available on all OBD scanners, which is why you need an advanced scanner.

- You now have to follow the instructions on the scanner as the scanner takes you through it.

- Afterward, turn the engine on and leave the car engine to run for some time.

- Then turn off the engine and disconnect the OBD scanner. And it is done.

How to Relearn a Crankshaft Position Sensor with scanner

How do you manually relearn a crankshaft position sensor?

To manually relearn your crankshaft position sensor, ensure that all electrical connections between your battery and starter motor are secure and working properly. Once these have been checked, locate the Manual Relearn button on your car’s diagnostic port (usually located near or under the steering wheel).

Pressing this button will initiate a process known as “crank-relearn,” which will allow you to reset any stored data from previous uses of your engine’s crank sensors so they match up correctly again for optimal performance levels once more.

As a final point, after pressing the manual release button, start the car by inserting the key into the ignition switch and allowing the computer system to finish its work before shutting down the engine.

If done successfully, new information regarding the crank position sensor should be uploaded into the ECU memory bank and ready for use. Start the vehicle again by inserting the key into the ignition switch.

Take note:

Manually relearning a crankshaft position sensor requires following specific procedures outlined in detail within the owner’s manual for the particular make and model automobile being serviced.

But the overall concept behind the task itself remains relatively simple regardless of the type of car being worked on since only a few easy-to-follow steps must be taken to complete the job correctly every time.

Conclusion

While temporarily fixing a crankshaft position can save you some cash, it’s also worth noting that these methods could worsen existing conditions. So caution must always be taken when attempting DIY approaches! So in this article, we discussed how to relearn a crankshaft position sensor manually, a temporary fix for crankshaft position sensor and what happens if you don t relearn a crankshaft position sensor. I hope this helps you. Please share this post.

Related: Where is the camshaft position sensor located on a 2007 Nissan Maxima

Uchenna is a Radiographer and Auto parts mechanic who recently got his automotive diploma as an auto repair technician, and since then, has worked on fixing various car problems.

Working as just a radiographer, Uchenna didn’t just get all the fulfillment he desired, because he truly loved doing things tilted toward cars. As a kid, he would take apart his toy cars to see how they worked and would spend hours tinkering with his bike.

So, in 2017 he made the tough decision to become an auto mechanic. He threw himself into his studies and now loves every aspect of what he does.

He gets to work with his hands, solving problems and bringing cars back to life, and sharing his knowledge and easy quick-fix guide online are all part of what makes him feel fulfilled.